Siemens Global Training

Siemens Virtual Training

As a leader in the global energy industry, Siemens is at the forefront of using Digital Technologies to improve products and services.

Virtualization of training is a high priority as technologies provide new opportunities to improve skills, safety, and provide opportunities for significant cost savings for Siemens and its customers.

Virtual training has been used within Siemens for many years, however, the pace at which virtual and augmented reality technologies are developing provides new opportunities to accelerate digitalization initiatives across all of Siemens businesses.

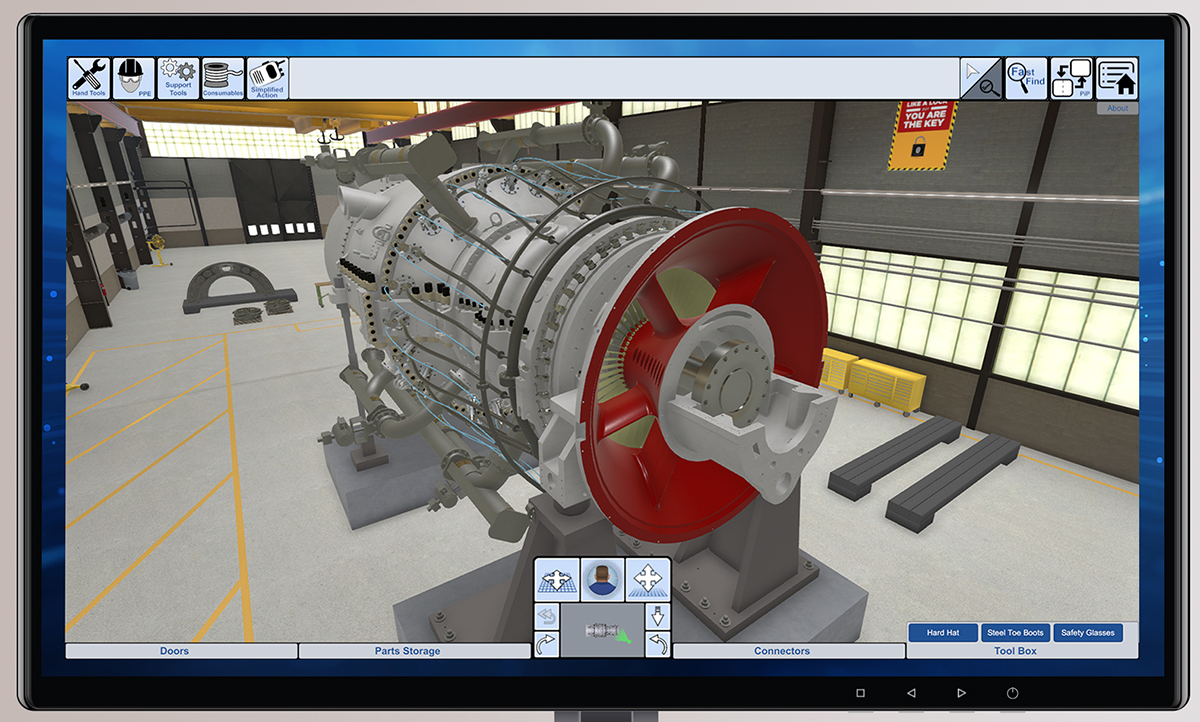

One of the critical success factors for virtual training is being cost-effective and highly scalable across multiple technologies with quality performance of real-time graphics. To achieve this Siemens selected VE Studio Virtual Training Development Platform which utilizes Unity’s real-time 3D development platform. VE Studio for Unity provides Siemens with a comprehensive platform on which to develop virtual training and field service applications quickly and cost-effectively by using the proven workflow and tools. Unity’s platform provides the ability to deploy high-fidelity applications on any device using the power of Unity’s engine. Siemens is currently conducting its virtual training using the HP Reverb for VR and the Microsoft HoloLens and the Magic Leap One for AR.

SGT6-8000 Hot Gas Path Inspection

Development of the first Siemens virtual training application began in 2016 with the goal of reducing the time and cost of training new technicians on a Hot Gas Path Inspection on Siemens SGT6-8000H Gas Turbine.

This project involved creating a virtual simulation of the SGT6-8000H Gas Turbine to teach the procedures required to perform this particular inspection. This virtual environment enabled showing the procedures visually in virtual reality (Teach). Enabling the technicians to explore the turbine and the procedures by interacting with the equipment (Practice) and then to test their skills through an interactive assessment process (Assess).

Initial results of the project provided the following data showing significant improvements in both time and retention:

- OVERALL TRAINING TIME REDUCED BY 66%.

- 13% INITIAL PASS RATE IMPROVEMENT USING THE VIRTUAL TRAINING SOLUTION VS. TRADITIONAL CLASSROOM LECTURE MODEL.

These positive results have led the development of virtual training and field service applications across a number of different product lines and have transformed how Siemens trains it field services technicians.

“We now approach virtual training as part of an integrated and holistic training curriculum,” says Kevin Carpenter, Global Training Network Director.

“We can provide capabilities and experiences virtually that we could not provide in the classroom or even during hands on training due to cost and safety considerations.”

SGT6-4000F Hot Gas Path Inspection

The SGT6-4000F was the next major project for the Global Services team managed by Siemens’ training team located in Berlin, Germany.

This project required a global development team from the United States and Europe to set up project infrastructure in order to manage the joint development effort.

The global development team was able to reduce development time on the SGT6-4000F by over 30% from the SGT6-8000H due to the capabilities of the VE Studio workflow to support multi-location projects and the experience the development teams gained on the first project.

One of the benefits of the database-driven architecture of VE Studio for Unity is the repackaging of content to create other training applications. Using the SGT6-4000F content, the team has developed additional modules such as a visual turbine blade inspection training that is suited for use in a fully immersive Virtual Reality experience.

In this application, a technician uses Virtual Reality to be completely immersed in the virtual SGT6-4000F turbine and is required to identify potential damage to components inside of the gas turbine. This training is able to provide immediate feedback to the technician and assess performance to aid the technician in becoming more proficient on identifying damage and taking the subsequent corrective action.

SGT-400 Turbine Removal

Building on the success of the large frame turbine trainers, Siemens expanded the use of virtual training to its fleet of industrial gas turbines.

The SGT400 is a 10-15 MW gas turbine commonly used in factories, oil rigs and other similar applications. The turbine is typically housed in an enclosure with other components and is sometimes referred to as a “package” so that it can be easily transported and installed.

Periodically, the turbine needs to be removed from the package in order to be serviced or repaired. This procedure is not routine or performed frequently so technicians need to be familiarized with the procedures prior to arriving at site and conducting the removal.

One of the design requirements was to have all of the procedures available for both desktop and fully immersive virtual reality use.

The development team was able to directly implement this capability due to its database-driven architecture, the workflow built into VE Studio, and the multi-platform deployment capability of Unity.

The capability to use this training in both desktop and fully immersive virtual reality provides Siemens technicians with tremendous flexibility on access to the training applications via their internal cloud.

Zero Harm Culture

Safety Training & Assessment

Recently, Siemens has implemented a global company-wide initiative or a “Zero Harm Culture” campaign aiming to improve safety, health, and well-being.

After experiencing such great success with its Digitalization initiative for virtual maintenance training, Siemens decided to create a training module using VE Studio to educate and foster its “Zero Harm” safety culture. The initial project created a virtual game that would assess workers’ awareness of various OSHA related requirements. Siemens used existing content from the SGT6-8000H curriculum as a baseline for the application.

“This game is now available to all 80,000 Siemens Gas and Power employees via the internal Intranet. This application has really helped to create awareness about the power of virtual reality technologies to educate workers about important topics. With virtual reality, we can put the employees into dangerous areas and teach them how to spot potentially dangerous situations and perform corrective actions. I think this is a real game-changer for our business and for the industry,” says Carpenter.

One of the design requirements was to have all of the procedures available for both desktop and fully immersive virtual reality use.

The development team was able to directly implement this capability due to its database-driven architecture, the workflow built into VE Studio, and the multi-platform deployment capability of Unity.

The capability to use this training in both desktop and fully immersive virtual reality provides Siemens technicians with tremendous flexibility on access to the training applications via their internal cloud.

In Summary

Digitalization is a top priority for Siemens and training is an area where technologies such as virtual reality, augmented reality, and cloud services are being used to create new digital models of training and field services. With employees on nearly every continent, the challenge for Siemens is finding a way to leverage virtual technologies to improve training in a scalable, cost-effective manner for its global workforce. The power generation market is becoming more decentralized and demands a portfolio of physical and digital technology resources and training. Siemens has partnered with DiSTI in its initiative to develop a long term solution to digitalize globally accessible training.

Inquire about our professional solutions today.

Start your developer journey with our solutions now.

We will use your information to respond to your inquiry. We may also contact you about our products and services. You may opt-out at any time using the unsubscribe link in messages you receive from us. You can learn more about how we handle your personal data and your rights by reviewing our privacy policy.